Tools Used: Unity Engine, Monday.com Scheduling Tool, Microsoft Excel, Zoom, Google Meet, Microsoft PowerPoint, Photoshop, Slack

The Smart Factory was a project specifically for Mitutoyo, a Metrology company headquartered in Japan. The idea of this project was that Mitutoyo had specifically requested a virtual version of their Smart Factory, a large and cumbersome exhibit to take with them from trade-show to trade-show. If they could instead change it to a two-screen exhibit that animated the Smart Factory in a way that is both informative and accurate, they wouldn’t need to bring around a multi-ton exhibit.

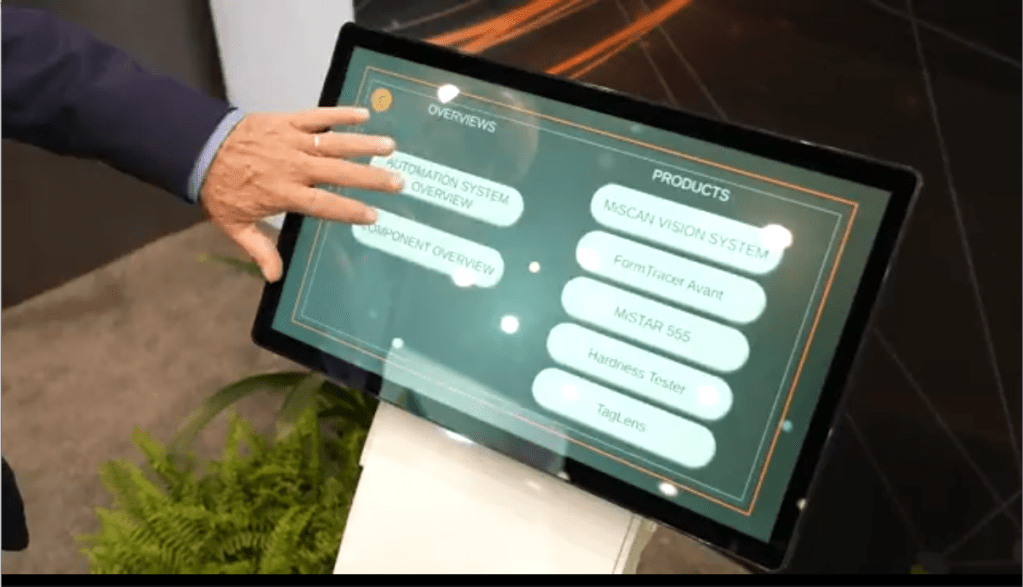

The Smart Factory consists of a large monitor that presents the Smart Factory itself, animated accurately to how the actual Smart Factory would work, and a smaller touchscreen on a pedestal, so people can change what they’re looking at and also read information about the current selection.

I was Associate Producer on this project, so I was the communicative bridge between our team and Mitutoyo. Furthermore, I was the main developer on this project, which was set to be debuted at IMTS 2022 in Chicago. The development time was around 3 months, and I was in charge of getting all of the various factory parts and animations lined up correctly, scripting camera movements and animation trees to make sure it was all as accurate as possible to the real Smart Factory. I also was the main contact for Mitutoyo’s marketing team, being sent all of the information that would be displayed on the smaller touchscreen, and using a bit of UI design and coding to display it to the client’s specifications. Anything that wasn’t done by me, usually an artist or animator, I met with and scheduled their tasks on Monday, making sure to keep the project in scope not only for them, but for our clients who were providing the information as well.

The main challenge of this project was it’s unique two-screen connection. Unity, while perfectly fine with using two screens for an application, will force users to use screen 1 for the touch-screen specifically if there’s a touch-screen involved. An interesting hiccup also occurred when Mitutoyo realized that their own Smart Factory was a bit slow. As a solution, I suggested we simply speed up the conveyor belt after a selection and no more. That way the actual important animations, the robots moving pieces and the measurement machines, were still accurate and able to be viewed sooner. This project was a huge success, garnering the attention of Mitutoyo’s own EU branch, and as a result of speaking with the head of marketing of EU Mitutoyo, we wound up on an extension of this project months later, translating it to 12 other languages for European trade-shows and making some adjustments to the information presented on the touch-screen.